SBZ Extreme Pressure/Anti-Wear Additives are suitable for manufacturing compressor and hydraulic fluids, gear oils, and greases to produce high-performance industrial lubricants to protect across a wide range of applications.

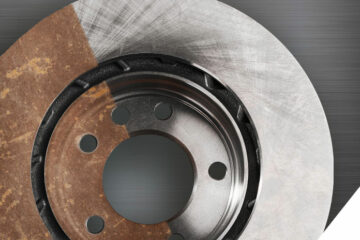

Extreme pressure

additives react with metal surfaces during operation at high pressures and

temperatures, creating a protective layer that reduces wear between two mating

metal surfaces. Anti-wear additives perform similarly but tend to operate under

lower pressures and temperatures.

Anti-wear additives

used are based on Fats, Zinc, and Phosphates. Such additives are common

ingredients in hydraulic oils. Extreme Pressure (EP) additives, based on Sulphur

and/or Chlorine, apply to applications where temperatures and loads are very

high, such as in gearbox applications.

Extreme Pressure

additives are usually used under heavier loads, at high temperatures, and at

low speeds to prevent catastrophic failure or seizing of the application.

Common examples of Extreme Pressure additives are molybdenum disulfide,

graphite, sulphurised olefins, and dialkyl dithiocarbamate complexes.

SBZ Extreme Pressure/Anti-Wear Additives

are suitable for manufacturing compressor and hydraulic fluids, gear oils, and

greases to produce high-performance industrial lubricants to protect at high

pressure and temperature where contaminants may be present.