Corrosion Inhibitors are substances that effectively reduce metal corrosion when introduced in small amounts.

These inhibitors work by slowing down the corrosion rate of metals in the given setting. Passivation, poisoning, precipitation, and surface adsorption are the methods through which corrosion inhibitors deter metal corrosion.

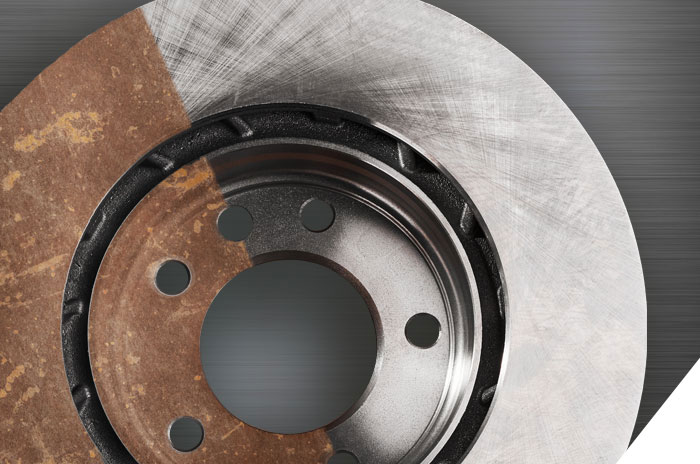

Utilised to prevent rusting and anodic corrosion of metals, corrosion inhibitors often involve coating the metal surface with a passivating layer. Oxygen scavengers, acting as corrosion inhibitors, react with dissolved oxygen to prevent cathodic corrosion.

Corrosion inhibition through adsorption is a surface-oriented process where inhibitor molecules replace water molecules adsorbed on a metal surface.

These inhibitors are widely used across industries and can also be found in consumer products, often in spray form combined with a lubricant and sometimes a penetrating oil. They can be added to water to prevent lead or copper leaching from pipes.

Major industries employing corrosion inhibitors include oil and gas exploration, petroleum refining, chemical manufacturing, heavy manufacturing, water treatment, and product additive industries.

SBZ provides oil and water-soluble corrosion inhibitors to safeguard against rust and oxidation.

Other Key Benefits:

- Range of ash and ashless technologies available.

- Wide application range covered.